EV Tools

April 23, 2025The Future of Electric Vehicle Maintenance and Innovation

The global shift towards electric vehicles (EVs) is accelerating faster than ever. With governments, manufacturers, and consumers focusing on sustainability and clean energy, the demand for advanced EV tools is growing. As we enter 2025, the landscape of EV maintenance, diagnostics, and repair is evolving rapidly, making it crucial for workshops, technicians, and enthusiasts to stay updated with the latest technologies.

This blog explores the key trends, essential tools, and innovations shaping the EV industry in 2025.

Why EV Tools Are Important in 2025

Unlike traditional internal combustion engine (ICE) vehicles, EVs rely heavily on battery technology, electric drivetrains, and complex electronic systems. Servicing them requires specialized tools designed for:

- Battery diagnostics and replacement.

- High-voltage safety testing.

- EV charging infrastructure maintenance.

- Software diagnostics and updates.

Without the right EV tools, it becomes difficult—and even dangerous—to perform proper maintenance and repairs.

Key Trends in EV Tools for 2025

1. High-Voltage Safety Equipment

As EV batteries operate at high voltages (often above 400V), safety is a top priority. In 2025, workshops must be equipped with:

- Insulated gloves and tools.

- Voltage detectors.

- High-voltage training kits.

This ensures both technician safety and compliance with international EV servicing standards.

2. Advanced EV Diagnostic Scanners

Modern EVs rely on software-driven systems. Advanced OBD-II and EV-specific diagnostic tools in 2025 now include:

- Battery health analyzers (measuring capacity, charging cycles, and degradation).

- Thermal management monitoring tools for battery cooling systems.

- Over-the-air update compatibility for manufacturers’ software.

Such tools help identify issues before they become costly repairs.

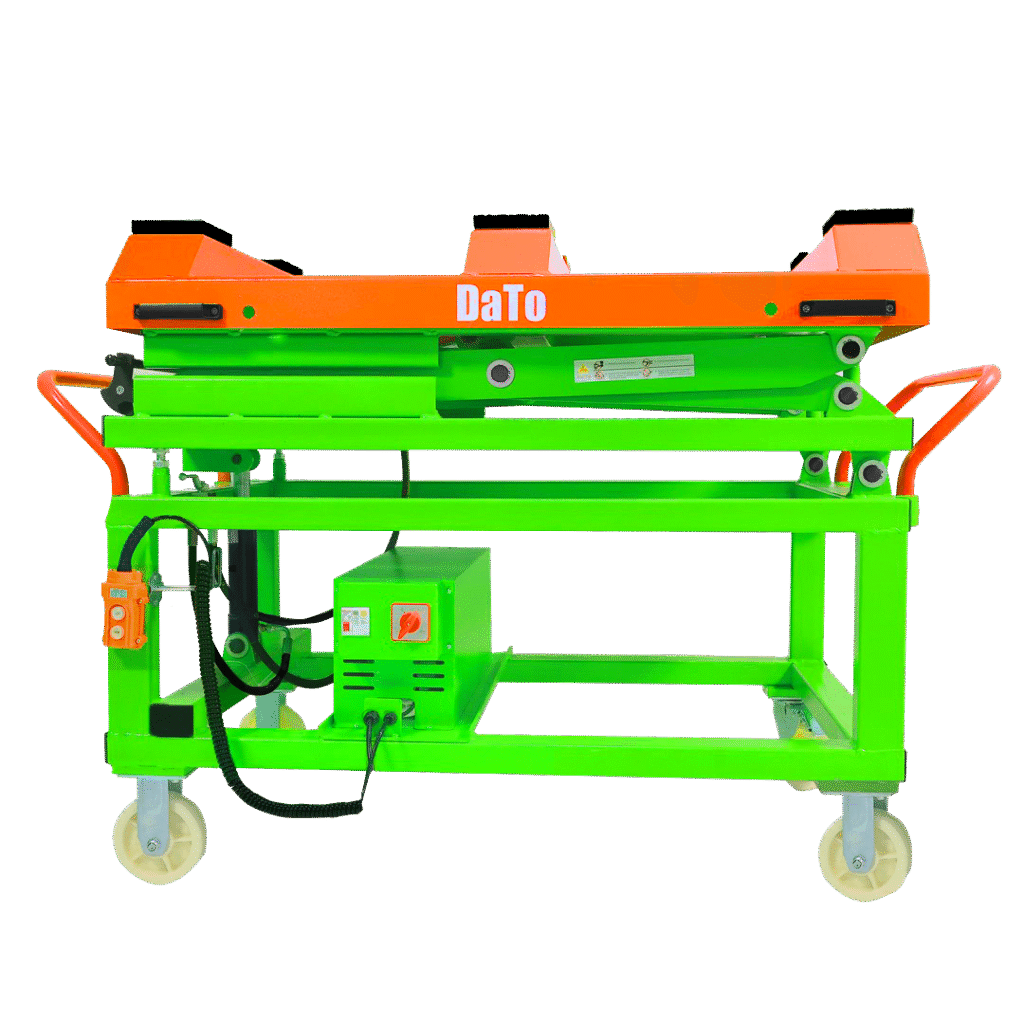

3. Battery Lifting and Handling Tools

As EV batteries are large and heavy, safe removal and installation require hydraulic lifting tools, stands, and supports. In 2025, improved battery handling equipment is designed for:

- Faster removal and replacement.

- Improved workshop ergonomics.

- Reduced risks of battery damage.

4. EV Charging Station Testing Tools

With the rapid expansion of charging networks, tools for testing charging stations are essential. These tools measure:

- Power delivery accuracy.

- Safety features like overload protection.

- Communication protocols between EV and charger.

Workshops and fleet operators in 2025 increasingly invest in charging station analyzers.

5. Software and Cloud-Based EV Tools

A major 2025 trend is the integration of cloud-based diagnostic platforms. These allow:

- Remote vehicle monitoring.

- Predictive maintenance alerts.

- Real-time data sharing between EV manufacturers and service centers.

This reduces downtime and improves efficiency for EV owners.

Essential EV Tools Every Workshop Needs in 2025

🔧 High-Voltage Multimeter

Specialized multimeters designed for EVs allow safe measurement of voltage and current in battery systems.

🔧 Insulated Hand Tools

Every technician requires insulated pliers, screwdrivers, and wrenches to work safely around high-voltage systems.

🔧 Thermal Imaging Cameras

Used to detect hotspots in batteries, motors, and charging equipment, thermal imaging ensures preventive maintenance.

🔧 Battery Balancers and Analyzers

These tools monitor battery performance, charge levels, and cell balancing, which is vital for extending EV battery life.

🔧 Lifting Jacks and Stands for EVs

Since EV batteries are mounted under the vehicle, specialized lifting systems make maintenance efficient.

The Role of Training Alongside EV Tools

Having the right EV tools is only half the solution. In 2025, technician training is equally important. Workshops must ensure that staff are skilled in:

- Safe handling of high-voltage systems.

- Using diagnostic scanners effectively.

- Following international EV maintenance guidelines.

Many tool manufacturers now bundle training programs with their equipment, ensuring technicians are always prepared.

The Future of EV Tools Beyond 2025

Looking ahead, the next generation of EV tools will likely include:

- AI-powered diagnostics for predictive maintenance.

- Robotic arms for automated battery removal.

- Wireless charging station analyzers.

- Augmented reality (AR) glasses for technician guidance.

These advancements will further simplify EV servicing and enhance efficiency across workshops worldwide.

Conclusion

The year 2025 marks a significant milestone in the evolution of EV tools. From high-voltage safety gear to advanced diagnostic systems, the tools used for EV maintenance are more advanced, precise, and connected than ever before.

For workshops, fleet operators, and individual EV owners, staying updated with these innovations is critical. Investing in the right EV Diagnostic tools 2025 not only ensures efficient servicing but also guarantees safety and reliability in the fast-growing electric vehicle market.

As EV adoption continues to rise globally, those equipped with the right tools and training will lead the way in this exciting automotive revolution.